MTM uses advanced packaging design simulation technology to drive process R&D and manufacturing ,which can give customers higher -quality services and experience than traditional OSAT. This also can empower product research and development design, production and manufacturing so MTM can provide customers with higher performance, integration, lower costs, and shorter market cycles and more competitiveness.

(Figure: MTM and traditional OSAT)

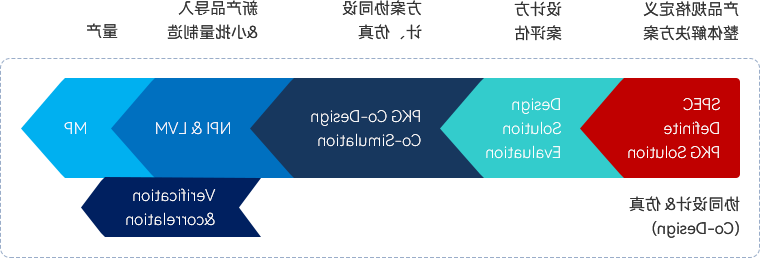

(Figure: Co Design collaborative design&simulation technology drives development from definition to mass production)

(1) Advanced Packaging Design:

- QFN/DFN Packaging Design

- RDL Circuit Design

- Flip Chip Packaging Design

- SiP Packaging Design

- Chiplet Packaging Design

(2) Electrical performance simulation analysis technology:

- PI (Power Integrity)analysis

- SI (Signal Integrity)analysis

- IBIS and SPICE electrical model extraction

- Near Field EMI and Far Field EMI

- Analysisof Interconnection Line Parameter Optimization

- Analysis of high-frequency and time-domain electrical performance of 5G products

(3) Structural stress simulation analysis technology:

- Structural Stress Simulation Analysis

- Chip stress, delamination, and crack analysis

- Bump stress, fracture analysis, reliability analysis for fatigue life prediction

- Stress analysis of chip microstructure

- Packaging Impact Cycle Simulation

(4) Packaging heat dissipation simulation analysis technology:

- Thermal performance analysis of packaging products

- JEDEC thermal resistance data and thermal model extraction

- PCB thermal performance analysis

- System level thermal performance analysis

- DOE analysis of thermal performance parameter optimization

(5) Packaging mold flow fill analysis:

- Transfer molding plastic packaging simulation analysis

- Compression molding simulation analysis

- Underfill Fill Analysis

- Metal lead offset analysis

- Leader frame offset analysis

Search for

Search for